ASME B16.9 is the standard for factory-made wrought butt-welding pipe fittings in sizes 1/2" through 48". Generally speaking, butt-welding pipe fittings are fabricated pieces of pipe that are used either to make changes of direction(elbow&return), close the pipeline end(end caps), branch from the main pipe(tee), or make a reduction in line size(reducer). They can be made from seamless pipes, welded pipes or plates.

As part of the piping system, pipe fittings must match as closely as possible in specification and rating to the pipe to which they are being attached. Butt-Welding end connection type requires to fill the weld groove between two pieces of pipe or fitting from inside surface to the outside surface of the pipe or fitting. Butt-Welding ends shall be furnished according to ASME B16.25.

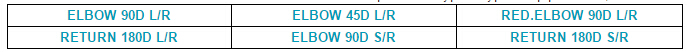

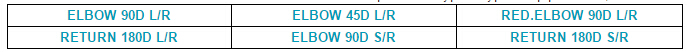

An elbow is one of the most often used butt-welding pipe fitting that is used to change the direction of pipeline to a certain angle. It can either turn up, turn down, turn right, left or any angle. The elbow sometimes is also called "bend" or abbreviated as "ell". ASME B16.9 stipulates 6 typical types of pipe elbow,

"L/R" refers to long radius of the center to end dimension which is equal to nominal pipe size multiplied by 1.5, while "S/R" refers to short radius of the center to end dimension which is equal to nominal pipe size. A short radius(SR) elbow creates a larger pressure drop in line and doesn't have the smooth & efficient characteristics the long radius(LR) elbow has. Hence short radius elbows are only used in space-limited application. Dimensions of 90-degrees, 45-degrees and 180-degrees elbow are shown within the standard. A reducing elbow is defined as a special elbow that has one large end and one small end. It takes the job of an elbow and a reducer. Besides, 180-degrees elbow is designated as 180-degrees return which is mostly used by equipment manufacturer to form heating or cooling coils.

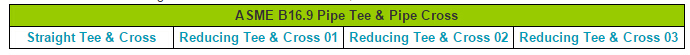

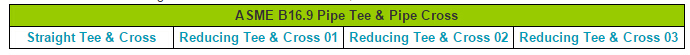

As above-mentioned, a pipe tee is used to branch from the main pipe. It's a three way fitting used to make perpendicular connections to a pipe. Pipe tee can be categorized into straight tee(branch & run outlets are the same pipe size) and reducing tee(branch outlet is smaller than main run outlet). A pipe cross is almost the same as a pipe tee except that it has penetrated-through two branch outlets perpendicular to the main run. Click below chart to view the dimensions and drawings of ASME B16.9 tee and cross,

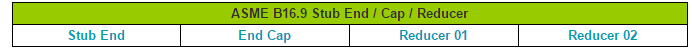

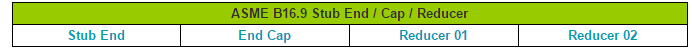

3. ASME B16.9: Concentric and Eccentric Reducer, Stub End and End Cap

Reducers are used to reduce the diameter of straight run pipes. Two type of reducers are available: Concentric Reducer and Eccentric Reducer. The concentric reducer maintains the same centerline at both the large and small ends of the fitting. The eccentric reducer has offset centerlines that will maintain a flat side on the top or the bottom of the fitting, depending on how the fitting is rolled prior to welding. The eccentric reducer is used in piperacks to maintain a constant bottom of pipe. Because pipe supports within a piperack are of the same elevation, a pipe must have a consistent bottom of pipe elevation so it can rest on each support throughout its entire length. Using a concentric reducer in a piperack would not permit the small diameter end of the pipe run to rest on the pipe support. Eccentric reducers are also used on pump suction nozzles to keep entrained air from entering the pump. By keeping a flat on top surface, vapor pockets can be eliminated. The centerline offset equals to "Large End I.D - Small End I.D / 2".

A Stub End is a sleeve shaped like a short piece of pipe with a weld bevel on one end and a narrow shoulder on the other end called the hub. The hub is the same outside diameter as the raised face (gasket contact surface) of a weld neck flange. The thickness of the hub is normally about 1/4" to 3/8". It is always used together with a mating lap joint flange(loose slip on). The lap joint flange is never in contact with the pipeline media but just acts as a backing or housing flange to hold the stub end. It is a cost-saving method when the flow media requires expensive in-contact base metal.

An End Cap works similarly to a blind flange. It seals an open end of pipe in butt welding connection type. It has ellipsoidal shape which conforms to the requirements given in the ASME Boiler and Pressure Vessel Code.

Hebei shengtian pipe-fitting group Co., ltd is specialized in manufacturing and exporting

forged flanges and buttwelded pipe fittings. In additation to the standard products mentioned above, we are also able to make non-standard, special-designed items according to customers’ requirement. Should any of the items be of your interests, please do not hesitate to contact us for latest information.